-

Home

-

About Scanautomatic

-

Exhibitors

-

Activities

-

Plan your visit

-

For Exhibitors

- Tickets and Opening hours

-

Digitalisation creates new opportunities for more sustainable and inclusive production. This is the view of Johan Bengtsson at the Gothenburg Institute of Technology, who wants to spread knowledge about the opportunities offered by new technology – not least to strengthen the competitiveness of Swedish industry.

Digitalisation creates new opportunities for more sustainable and inclusive production. This is the view of Johan Bengtsson at the Gothenburg Institute of Technology, who wants to spread knowledge about the opportunities offered by new technology – not least to strengthen the competitiveness of Swedish industry.

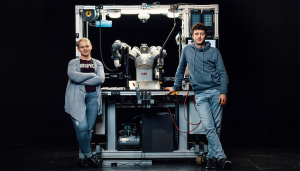

As Technology Development Manager at Gothenburg Technical College, Johan Bengtsson is passionate about two things – technology and sustainability. He is taking part at Scanautomatic as the Project Leader of Production for Future, a non-profit project funded by Vinnova, the Västra Götaland region and several partner companies. Its aim is to create and spread knowledge about sustainability, diversity and technology.

What does sustainable production mean to you?

– Making the best use of the resources we consume. This applies to land and water as well as energy and other raw materials. It’s about working proactively to increase efficiency and make the most of resources in a circular flow. Economic sustainability is also important, as is social sustainability in terms of, for example, the physical and psychosocial working environment.

How can the focus on sustainability affect competitiveness?

– Companies that are at the forefront are better placed to attract good partners, while at the same time being able to recruit and retain good people more easily. That means sustainability is definitely a competitive asset and here in Sweden we have come a long way, not least because we have tough legislation.

What opportunities does digitalisation offer for sustainable development?

– Connecting machines used in production enables data-driven decisions and sharper analysis. It also means you can better visualise processes, which creates peace of mind in the factory. Operators can constantly see what needs to be prioritised and they can plan work better, resulting in smarter, more sustainable production.

What is important to consider in developing a sustainable business?

– Gain knowledge, do a baseline analysis, set goals, prioritise and follow up. Classic change management, where the most important thing is to get the employees on board. Remember that every decision you make has an impact, from the products you choose to make to the materials and processes you use. And it’s important to think about the whole lifecycle from the start – everything should be reusable or recyclable downstream.